В современном цифровом мире системы бесперебойного питания (ИБП) играют важнейшую роль в защите чувствительного оборудования и обеспечении непрерывности бизнеса. Однако самой большой проблемой остаётся непредвиденный отказ компонентов ИБП, особенно аккумуляторов, который может привести к дорогостоящим простоям, потере данных и сбоям в работе. К счастью, достижения в области искусственного интеллекта (ИИ) кардинально меняют обслуживание ИБП благодаря предиктивной аналитике, помогая компаниям выявлять проблемы до их эскалации, оптимизировать производительность системы и снижать эксплуатационные расходы.

Почему прогностическое обслуживание важно для систем ИБП

Традиционное обслуживание ИБП в значительной степени основано на плановых проверках и оперативных ремонтах. Этот подход часто не позволяет обнаружить едва заметные признаки износа, что приводит к неожиданным сбоям, которые могут поставить под угрозу работу критически важных систем. Прогностическое обслуживание на основе искусственного интеллекта меняет эту парадигму, непрерывно отслеживая состояние системы и предвосхищая потенциальные сбои.

- Непрерывный мониторинг в реальном времени

Современные системы ИБП оснащены различными датчиками, которые отслеживают ключевые рабочие параметры, включая напряжение аккумулятора, ток, температуру, внутреннее сопротивление и циклы заряда/разряда. Этот комплексный сбор данных осуществляется круглосуточно, что позволяет получить целостное представление о текущем состоянии системы ИБП. Постоянный мониторинг обеспечивает раннее обнаружение даже самых незначительных отклонений от нормальных условий эксплуатации, что критически важно для предотвращения каскадных отказов. - Аналитика на основе данных

Большой объём данных, собираемых датчиками ИБП, анализируется с помощью передовых алгоритмов искусственного интеллекта и методов машинного обучения. Эти модели изучают нормальные режимы работы каждого ИБП и могут быстро выявлять отклонения или тенденции, указывающие на ухудшение состояния или надвигающийся отказ. Это выходит за рамки простых пороговых сигналов тревоги и позволяет проводить тонкую, контекстно-зависимую диагностику, что снижает количество ложных срабатываний и повышает точность обслуживания. - Раннее обнаружение и предотвращение неисправностей

Одним из наиболее ценных аспектов предиктивного обслуживания на основе ИИ является его способность прогнозировать потенциальные отказы оборудования за несколько дней или даже недель до их возникновения. Выявляя едва заметные признаки, такие как постепенное увеличение внутреннего сопротивления аккумулятора или аномальные колебания температуры, специалисты по техническому обслуживанию могут вмешаться заранее, заменив или отремонтировав компоненты до того, как катастрофический отказ приведёт к простою или потере данных.

Как ИИ обеспечивает прогностическое обслуживание систем ИБП

Прогностическое обслуживание на основе искусственного интеллекта объединяет данные датчиков, историю производительности и факторы окружающей среды для создания высокоточных моделей состояния компонентов ИБП. Ключевые функции включают:

- Обнаружение аномалий

Системы искусственного интеллекта используют статистический анализ, распознавание образов и машинное обучение для выявления отклонений в поведении, которые операторы могут пропустить. К ним относятся скачки напряжения, неожиданное падение ёмкости аккумулятора, необычные температурные профили и нерегулярные циклы зарядки/разрядки. Раннее обнаружение этих отклонений может предотвратить ухудшение работы системы и продлить срок службы ИБП. - Автоматические оповещения и рекомендации

Системы на базе искусственного интеллекта, основанные на прогнозных моделях, генерируют оперативные оповещения, в которых указывается характер обнаруженной проблемы, её срочность и рекомендуемые меры по её устранению. Эти оповещения часто интегрируются в централизованные панели мониторинга и могут быть настроены для оповещения обслуживающего персонала по электронной почте, SMS или push-уведомлениям в мобильном приложении, что обеспечивает своевременное реагирование даже при отсутствии персонала на объекте.

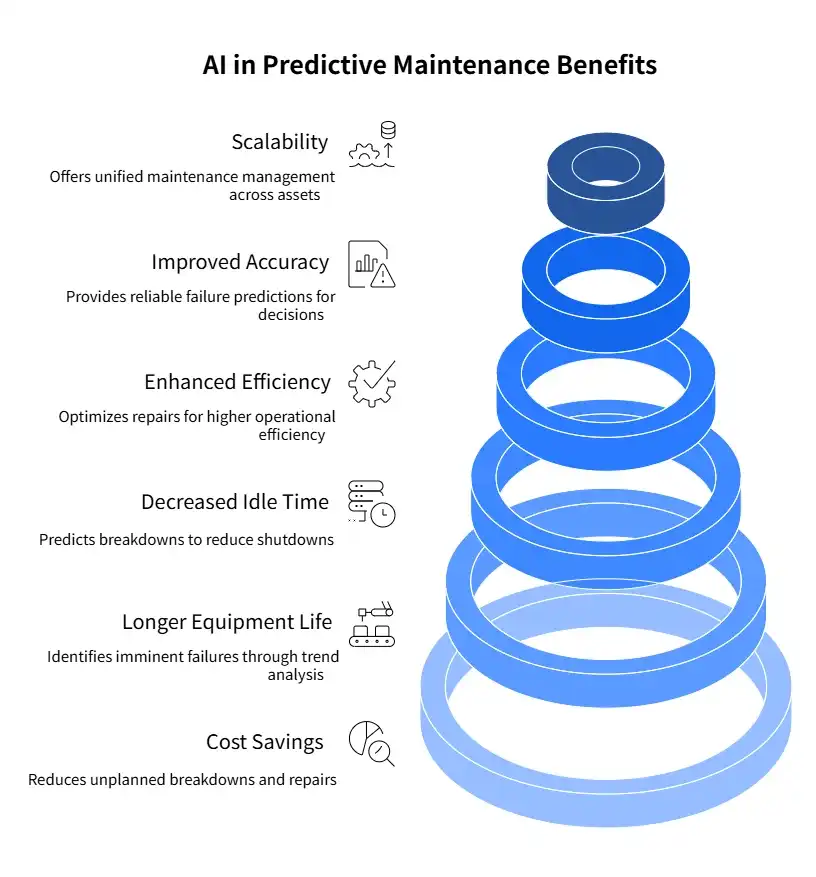

Преимущества предиктивного обслуживания на основе ИИ

Внедрение ИИ при обслуживании ИБП обеспечивает многочисленные эксплуатационные и финансовые преимущества:

- Сокращение времени простоя и повышение надежности

Предвидя сбои до их возникновения, предиктивное обслуживание минимизирует непредвиденные сбои, которые могут нарушить критически важные процессы. Это обеспечивает бесперебойное электроснабжение центров обработки данных, медицинских учреждений, телекоммуникационных сетей и других сред, где бесперебойность работы критически важна. - Оптимизированный график технического обслуживания

Переход от жёстких календарных циклов технического обслуживания к планированию на основе данных сокращает количество ненужных осмотров и ремонтов. Техническое обслуживание выполняется точно в момент необходимости, что позволяет экономить ресурсы и повышать эксплуатационную эффективность. - Увеличенный срок службы оборудования

Своевременное вмешательство, основанное на данных в режиме реального времени и анализе с помощью искусственного интеллекта, помогает предотвратить преждевременную деградацию аккумулятора, вызванную перезарядом, глубоким разрядом или экстремальными температурами. Такая защита продлевает срок службы компонентов ИБП и снижает капитальные затраты. - Эффективность затрат

Предотвращение аварийного ремонта и сокращение частоты планового обслуживания снижают общие эксплуатационные расходы. Организации могут более стратегически распределять бюджеты на техническое обслуживание, концентрируясь на приоритетных проблемах, выявленных с помощью аналитики ИИ. - Повышенная безопасность

Предотвращение отказов и перегрева аккумуляторных батарей снижает такие риски, как возгорание или утечка химикатов, защищая персонал, оборудование и объекты.

Лидерство Gottogpower в обслуживании ИБП с использованием ИИ

В ГоттогпауэрМы стремимся расширить границы технологий ИБП, внедряя функции предиктивного обслуживания на основе искусственного интеллекта во все наши линейки продукции. Наши передовые решения в области ИБП включают:

- Интеллектуальный мониторинг состояния батареи

Наши системы непрерывно отслеживают параметры аккумулятора и применяют аналитику на основе искусственного интеллекта для точной оценки состояния и раннего оповещения. Этот проактивный подход помогает клиентам избегать незапланированных простоев и оптимизировать циклы замены аккумуляторов. - Удаленный мониторинг с поддержкой облака

Благодаря безопасным облачным платформам операторы могут получать доступ к данным о производительности системы в режиме реального времени из любой точки мира. Такая удалённая видимость особенно ценна для многообъектных операций и объектов, требующих круглосуточного контроля. - Интеллектуальные инструменты планирования технического обслуживания

Программное обеспечение Gottogpower предоставляет прогнозные оповещения, подробную диагностику и рекомендации по графику технического обслуживания. Это позволяет специалистам по техническому обслуживанию сосредоточить усилия там, где они нужнее всего, повышая производительность и снижая затраты. - Модульная и масштабируемая конструкция

Наши системы бесперебойного питания (ИБП) разработаны с учётом меняющихся требований к инфраструктуре. Интеграция предиктивного обслуживания на базе искусственного интеллекта гарантирует, что даже при расширении систем они будут оставаться надёжными и простыми в управлении.

Наши решения в области ИБП на базе искусственного интеллекта успешно внедрены в центрах обработки данных, медицинских учреждениях, телекоммуникационных компаниях и промышленных предприятиях по всему миру, помогая клиентам добиться беспрецедентной продолжительности бесперебойной работы, экономии средств и душевного спокойствия.

Будущее обслуживания ИБП: интеллектуальная, прогнозируемая экосистема

По мере того, как цифровые инфраструктуры становятся всё более сложными, а потребности в электроэнергии растут, потребность в интеллектуальном обслуживании ИБП на основе данных будет только возрастать. Прогностическое обслуживание на базе искусственного интеллекта быстро становится отраслевым стандартом, преобразуя подход организаций к защите критически важной энергетической инфраструктуры.

Выбор решений ИБП на базе искусственного интеллекта ГОТОВАЯ СИЛА гарантирует, что ваши резервные системы электропитания не только реагируют на изменения, но и управляются проактивно, обеспечивая стабильную и надежную подачу энергии именно тогда, когда это нужнее всего.