Embracing the AI Wave to Fulfil Arithmetic Potential – Experts in Liquid Cooling Solutions

Why Liquid Cooling is an Inevitable Trend for Smart Computing Centres?

Power density surge: AI training clusters commonly use high power consumption GPU/accelerator cards, and the power of a single cabinet far exceeds the limit of traditional air-cooling.

Demand for heat dissipation efficiency: The specific heat capacity and thermal conductivity of liquids are much higher than that of air (about 1,000-3,000 times higher), which can more efficiently take away the huge heat generated by chips.

Energy saving (PUE optimisation): Liquid cooling significantly reduces or even eliminates the reliance on air conditioning and powerful fans in the server room, significantly reducing the energy consumption of the cooling system and lowering the PUE (Power Usage Effectiveness) to close to 1.3 or even lower (air-cooled systems are usually above 1.5).

Reduced Noise: Liquid-cooled systems operate much quieter than high speed fan clusters, improving the working environment.

Increased Computing Density: More efficient cooling allows more, higher-performance computing devices to be deployed in the same space.

Improved Chip Performance and Reliability: More stable, lower chip operating temperatures help increase operating frequency and reduce heat-related electromigration and failure rates, extending device life.

Adaptability to High Temperature Environments: Liquid cooling is less sensitive to outdoor ambient temperatures, making it easier to utilise natural cooling sources (e.g., cold water towers, dry coolers) and reducing cooling costs.

Architecture de refroidissement liquide grand public pour centre informatique intelligent

There are two main categories, cold plate liquid cooling and immersion liquid cooling, each with its own advantages and application scenarios:

Key Considerations for Liquid Cooled Architecture for Smart Computing Centres?

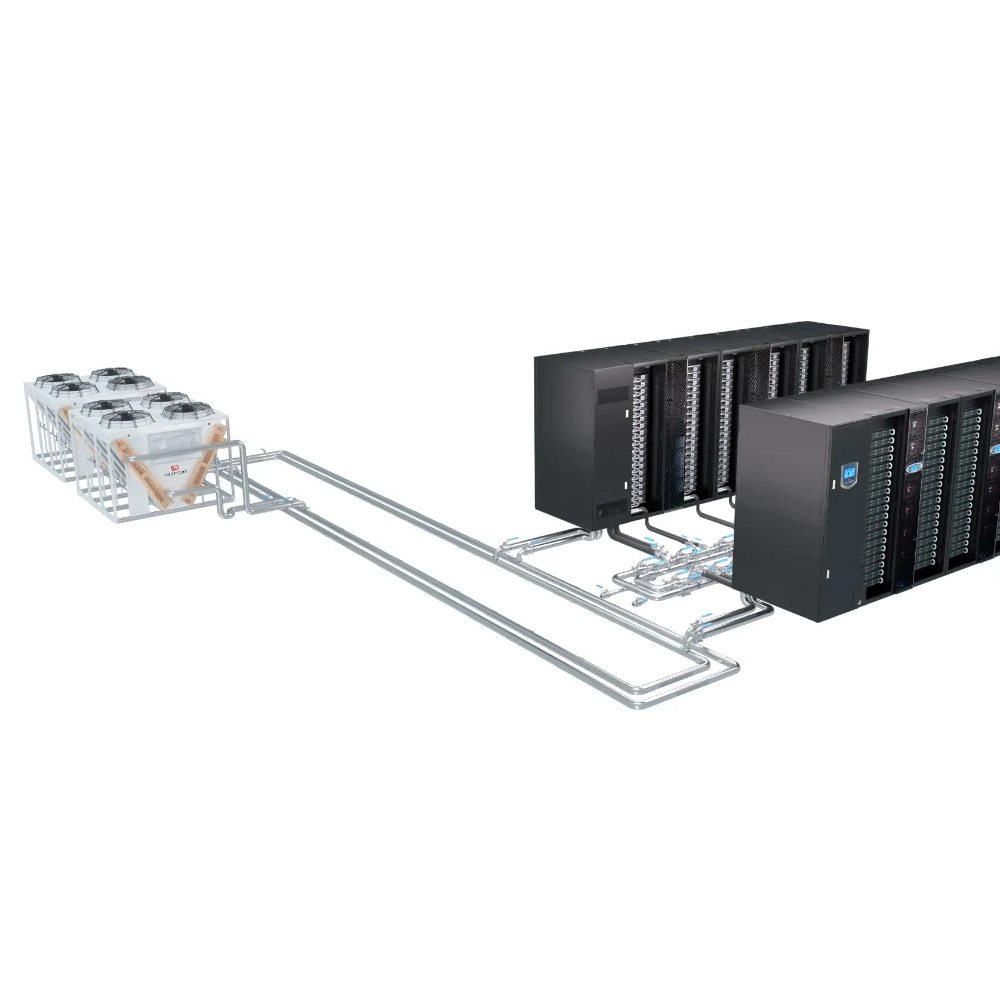

GT Full Chain Liquid Cooling Solution

GOTTOGPOWER gathers the industry’s top technical team, with core members from the former Emerson R&D core, who have been deeply engaged in the fields of heat transfer, materials, heat dissipation modules, and process technology design for many years. We are accelerating the evolution of the industry by relying on the advantages of our technologies.

Solution Introduction:

With the core of independent research and development of the whole chain, this solution deeply integrates thermodynamic design and intelligent control technology to address the pain points of heat dissipation bottleneck, energy consumption surge and security compatibility of high power density servers.

Through the design-manufacturing-delivery-after-sales service system, it provides customers with closed-loop services from customised solutions to continuous optimisation, ensuring that the data centre achieves ultra-high-density computing power deployment and green low-carbon operation.

Core Features:

● Rapid Deployment

➟ Modular prefabricated design greatly simplifies the on-site installation process.

➟ Significantly reduces the complexity of the project and the deployment time.

➟ Supports elastic capacity expansion, responding flexibly to business needs.

● High-efficiency Cooling

➟ Direct contact heat dissipation, precise control of chip-level temperature.

➟ Breaking through the traditional air-cooling density limitations, supporting ultra-high-power computing clusters.

➟ Completely eliminating hot spots, ensuring the continuous high-performance operation of hardware.

● Green Energy Saving

➟ Revolutionary energy efficiency improvement, significantly reducing the energy consumption of the cooling system.

➟ High-temperature heat recovery compatible design, activating the potential of energy reuse.

➟ High proportion of natural cooling source utilisation throughout the year, reducing carbon footprints.

● Low noise and vibration damping

➟ Mechanical vibration tends to be close to zero, enhancing the long-term reliability of the equipment.

➟ Breaking through the restrictions on the location of the server room, adapting to the deployment of a variety of scenarios.

● Safety and reliability

➟ Multiple security systems.

➟ Full stack of independently controllable components to ensure supply chain security.

● Intelligent control

➟ AI dynamic optimisation system: real-time adjustment of cooling parameters to achieve optimal energy efficiency.

➟ All-link state visibility: multi-dimensional sensing and predictive maintenance.

➟ Remote intelligent operation and maintenance: quickly locate anomalies to maximise system availability.

Featured Product:

Please fill the form below, and our experts will contact you to develop the optimal solution for your project.