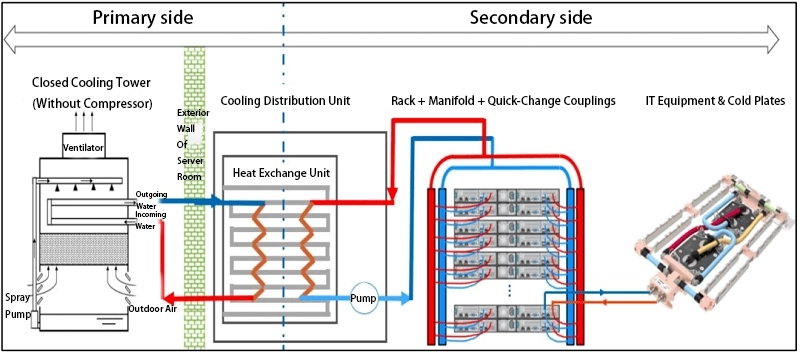

Refroidissement liquide par plaque froide:

Principe:

Une plaque de refroidissement métallique (généralement en cuivre ou en aluminium) est installée sur les composants clés (CPU, GPU, mémoire, etc.) qui génèrent beaucoup de chaleur. Le liquide de refroidissement circule dans des microcanaux à l'intérieur de la plaque et absorbe directement la chaleur de la puce. D'autres composants qui génèrent relativement peu de chaleur (par exemple, les disques durs, les alimentations, certains composants de cartes mères) utilisent encore l'air pour dissiper la chaleur.

Circuit de refroidissement : le liquide de refroidissement circule entre le CDU ou l'échangeur de chaleur au niveau de l'armoire à l'intérieur de l'armoire et la plaque froide du serveur. Le CDU/échangeur de chaleur transfère ensuite la chaleur à un circuit d'eau de refroidissement secondaire (par exemple, de l'eau réfrigérée) au niveau de la salle des serveurs.

Avantages :

Modifications relativement mineures du serveur (principalement au niveau des connexions du radiateur et de la tuyauterie), bonne compatibilité.

Peut être déployé progressivement, en mélange avec une présence refroidie par air.

Technologie relativement mature et meilleure chaîne industrielle.

Scénarios applicables : Densité de puissance modérément élevée (par exemple, 20 à 50 kW/armoire), exigences de compatibilité élevées pour la modernisation des installations existantes ou scénarios comme solution de transition.

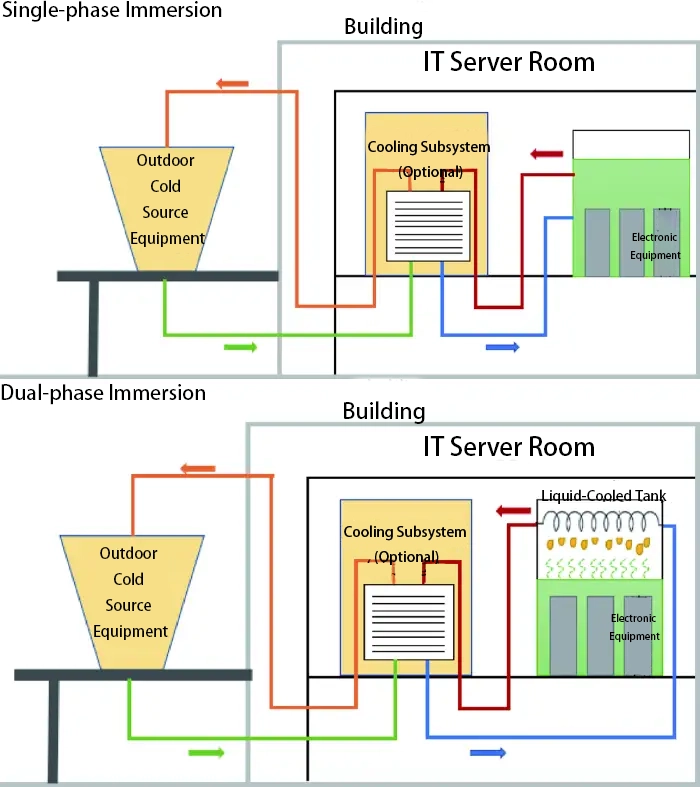

Refroidissement liquide par immersion :

Principe:

L'ensemble du serveur ou du nœud est entièrement immergé dans un liquide de refroidissement non conducteur. Ce liquide est en contact direct avec tous les composants électroniques et absorbe la chaleur.

Avantages :

Dissipation thermique ultime : contact direct avec résistance thermique minimale pour une efficacité de refroidissement maximale, gérant facilement des densités de puissance très élevées (> 100 kW/armoire).

Suppression complète des ventilateurs : Pas de ventilateurs à l'intérieur des serveurs, très faible bruit, réduisant encore la consommation d'énergie.

Déploiement haute densité : les serveurs peuvent être regroupés de manière compacte pour une utilisation élevée de l'espace.

Infrastructure simplifiée : Réduction drastique, voire suppression, de la climatisation des salles de serveurs, des conduits d'air, des planchers surélevés, etc.

Haute fiabilité : l’isolation contre l’oxygène et l’humidité réduit la corrosion et la contamination par la poussière et améliore la fiabilité de l’équipement.

Utilisation efficace des sources de refroidissement naturelles : particulièrement adapté à la combinaison avec des méthodes de refroidissement naturelles telles que les refroidisseurs à sec pour obtenir un PUE extrêmement faible tout au long de l'année.

Scénarios applicables : Centres de calcul à grande échelle nouvellement construits, scénarios avec une forte demande de PUE extrême et de densité ultra-élevée (par exemple, clusters de formation d'IA à grande échelle, centres de supercalcul).